by rchan454 | Jun 24, 2015 | Release

FLO923 PRODUCT DESCRIPTION: FL0923 is a thermally cured release coat. FL0923 makes use of a unique binding system, to retain high temperature stability while reducing stiction. The film thickness as applied ranges from .0005″ to .003″ and is not...

by rchan454 | Jun 24, 2015 | Protective Coatings for Wood

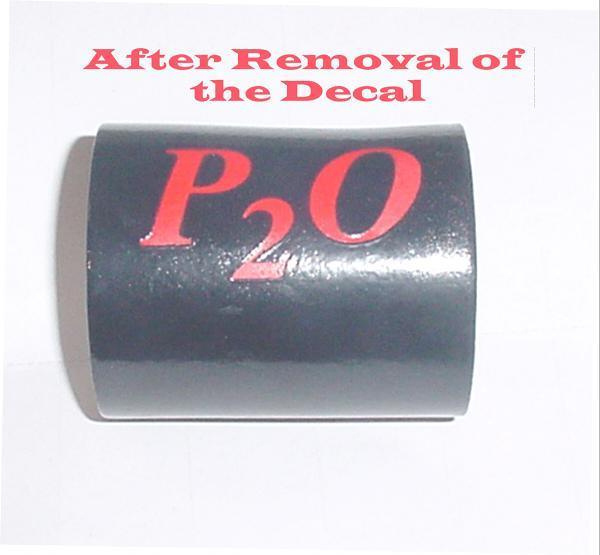

Liquid2O , also knowen as L2O PRODUCT DESCRIPTION: Powder coating is a popular method of protecting and enhancing the appearance of a part. It is a very “Green” technology and the use of this technology is expanding. However there are some applications...

by rchan454 | Jun 24, 2015 | Lubrication

CermaLube is an extreme pressure bonded ceramic lubricant which is best for rigid surfaces such as piston skirts, cam lobes, gears etc. It is water based and applies in a very thin film, no clearance changes necessary. It reduces friction, galling and scuffing and...

by rchan454 | Jun 24, 2015 | Corrosion Resistance, Heat Management

PrevCor™ PRODUCT DESCRIPTION: PrevCor™ can be applied to any exhaust system part or other metal surface to increase corrosion resistance. Designed as a base coat, PrevCor™ can be top coated with a variety of different coatings. PrevCor™ was formulated to reduce the...

by rchan454 | Jun 24, 2015 | Coatings for Composites, Industrial, Thermal Barrier

POWERKOTE PRODUCT DESCRIPTION: The PowerKote line was developed to provide high pressure and high temperature lubrication. PowerKote is available in a standard formulation, DFL-1, that will fit most needs. Versions are available that met FDA guidelines as well as...