Exhaust System Coatings

Exhaust System Coatings are designed to maintain adhesion at temperatures above the normal operating range of an exhaust system. Apart from their use as thermal barriers, they also protect against corrosion, chemicals, and more.

Carrera Air Cure Coatings

Protect both exhaust and internal engine parts with our Carrera line of air-cured coatings. No oven required.

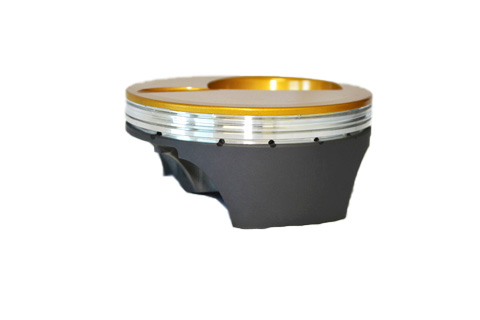

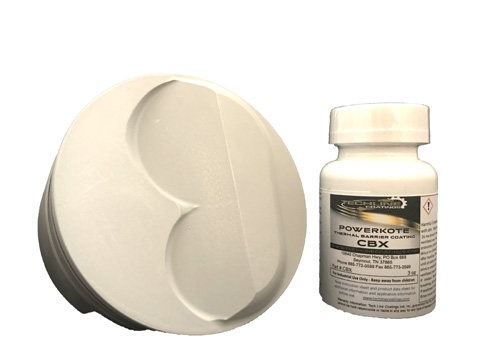

Internal Engine Coatings

TECH LINE makes available a full range of power-enhancing coatings for internal engine parts, including dry film lubricants, thermal barriers, and more.

Specialty Coatings

Apply any color powder without the need for electrostatic equipment with our LiquiPowdr. Or create a nearly endless number of colors to apply nearly any surface with our Carrera LTC

Industrial Coatings

Protect a multitude of products from heat, corrosion, chemicals, and extreme pressure applications. Protect their appearance and more.

Why Choose Us!

- We Are The Major Supplier To The Performance Aftermarket…And have been for over 30 years

- Our Products Are Preferred Worldwide.

- We Bring The Advantages Of Constantly Evolving Coating Technology To The Industrial And The Automotive Aftermarket.

Tech Line Coatings is the industry expert in thin-film technology. For over 30 years we are the trusted name when it comes to coatings for all of your specialized needs. With our extensive supply of standardized, OEM spec, and specialized coatings, we have a coating to fit your needs.

Our coatings have set the standard. Often imitated but never duplicated! Our customer base keeps growing and with good reason. Whether Industrial, Automotive, Marine, or Agricultural – we have a coating for you. Don’t miss out. See how you, too, can benefit from the experience and quality that comes from using Tech Line Coatings on your projects.

Keep watching the website and our Facebook page for new formulas, exciting tests, and new “coat-it-yourself” products for individuals!

Tech Line Coatings offer Product SDS Sheets for our customers and clients so they can have all the information they need regarding products and parts.

Tech Line Coatings offer Product Data Sheets for our customers and clients so they can have all the information they need regarding products and parts.

See our Products Catalog

It’s All about the Power! Manage friction and heat for greater performance!

Coatings For All Your Needs!

Dry Film Lubricants

Also known as solid film lubricants, provide a lubricating fill that reduces friction, inhibits galling and seizing and in some instances can aid in dispersing heat. The appearance is generally a charcoal gray and takes on a sheen upon burnishing. They are slippery and provide an extremely low coefficient of friction.

The two most important components are the binders and lubricating ingredients. Without a good binder, the coating will not stay in place and will simply cold flow or buff off in operation. Similar coatings using the same pigments but different binding systems can show a wide variation in load carrying capabilities, ranging from 100,000 psi to over 350,000 psi. The pigments determine the actual lubricating potential. PTFE (Teflon by DuPont Co.) as an example, is listed as having the lowest coefficient of friction (COF). However, under high speed and load, the COF of PTFE degrades while that of Molybdenum disulfide (MoS 2) improves until it is significantly better than PTFE. Other materials, individually or in combination, can enhance lubrication even beyond that of Moly and that is what we specialize in.

One of the obvious reasons for using a lubricating coating is to reduce friction, which improves wear, extends part life, and frees up H.P. normally lost to friction. A second major benefit is a reduction in part temperature. This is especially important to such parts as valve springs. Here the coating chosen is critical as certain materials can trap heat in a part. Not all coatings are created equal.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Thermal Barrier Coatings

Thermal Barrier Coatings (TBCs) are designed to manage the movement of heat.

TECH LINE has always been ahead of our time. For example, in the late-1980’s we developed the coating approved by McDonnell Douglas for the exterior of the X-30 Space Plane for protection against the enormous heat loads associated with atmospheric reentry during hypersonic flight. Our expertise in this area has been carried forward to serve a variety of industries and needs.

In some instances, such as exhaust systems, you want to keep the heat flowing through the part rather than being absorbed by it and manage the heat that reaches the surface so that it radiates away faster, to reduce surface temperature and to reduce heat transfer to nearby components. In combustion chambers, you want to use the heat generated by combustion to push down on the piston rather than bleed off into surrounding surfaces.

As a result of continued testing, we are learning that simple thermal barrier action is not the only characteristic that is important. In fact, certain TBCs will move an engine into detonation. TBC coatings can be made from a variety of materials. Ceramics get the most attention, though there are other materials that are superior in specific applications. The proper choice is critical to the overall function of the coating.

Combining TBCs with Thermal Dispersants can enhance the overall function of a component.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Thermal Dispersants

Being able to move and control heat is of tremendous importance. Excessive temperature can lead to metal fatigue, boiling fluids, damaging metal expansion, reduce electrical efficiency, and a host of other problems. Traditionally dealing with heat has been handled by expanding the radiating surface, constructing parts from materials that are more heat conductive, and using the color black.

With advances in thermal management methods additional ways of enhancing heat transfer now exist. TECH LINE has developed a Thermal Management System. Individual products such as TLTD can be utilized by themselves or in conjunction with other coatings to manage the flow of heat. TLTD is capable of transferring heat faster than the bare metal surface. While TLTD does make use of the color black, TLTD is more than a simple “black body” heat emitting coating.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Corrosion and Chemical Resistance

Corrosion and Chemical Inhibiting Coatings

The loss of effectiveness, reduction in part life and deteriorating appearance due to corrosion or chemical damage is of real concern.

For example…

In the oil and gas industry, components can fail due to exposure to sulfur/sulfuric acid.

In marine applications, components deteriorate and fail due to exposure to the elements, especially salt.

Radiating surfaces can lose effectiveness as corrosion forms an oxide layer, which is a thermal barrier.

Losing a well-matched/tuned header to rust is not only expensive but frustrating; a good aluminum manifold can become junk if the water inlet corrodes excessively. Keeping components clean and attractive is of concern when promoting your vehicle or the parts you manufacture to sponsors or customers.

Tech Line™ offers a variety of protective coatings that also enhance the appearance of a part. Many of these coatings will have additional benefits such as Thermal Barrier or Thermal Dispersant capabilities.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Wear Resistant

The applications for wear-resistant coatings are endless. Wear can be experienced in a variety of circumstances. Sliding, rotating, pulsing and even stationary components are subject to wear.

TECH LINE is constantly developing coatings to deal with wear.

For example…

- Sliding components such as pistons and hydraulic cylinders need lubrication beyond what liquid lubricants can provide.

- Slide rails and any surface with repetitive sliding motions can be coated to reduce wear and improve effectiveness.

- Rotating components such as bearings, gears, axles, hubs, impellers, shafts (of all kinds), rollers, agitators, and mixers.

Wear can also be experienced in environmental attacks; rain, snow, hail, dust, debris, chemical degradation. TECH LINE has developed coatings to withstand the elements for applications at sea such as drilling equipment, seawalls, and coatings for wood, plastics, and other materials used in harsh environments.

We developed a coating for a fireworks manufacturer to use on the inside of cardboard shells which protects against breach during ignition.

Coatings used in manufacturing glass to reduce the marking of the glass by the framework that holds the glass while it is heated and shaped.

Wear resistance for nuts and bolts to provide even torque as applied and released.

High-temperature clamps are protected by wear and corrosion so they can be disconnected when maintenance is required.

Reduce cavitation and wear in pumps.

Dry film lubricants can be used in both wet and non-wet lubricant environments.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Non-Stick/Release

There are many applications for coatings with a good release, non-stick characteristics, and fluid-shedding properties.

For example…

Non-stick cookware; Anti-graffiti; in high-performance engines, helps oil return to sump faster; marine applications to reduce friction and drag.

Non-stick coatings typically are thermal barriers though TECH LINE also has thermal dispersants with good release properties and can be made to be FDA-acceptable.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Conformal Coatings

Many times it is necessary to produce coatings that will conform to the final shape needed in operation because of the tight clearances that must be maintained or movement or flex within a component. TECH LINE has developed conformal coatings for superchargers, industrial air compressors, oil pumping equipment, pistons, and more.

Coatings can be built up to more closely match desired tolerances and then can wear, burnish or abrade as needed to provide the tightest, most lubricious fit possible (for example, to reduce the “rocking” movement of pistons during the stroke). TECH LINE’s first “build-up” and “reduced friction” coating was developed in 1987. These and many other TECH LINE COATINGS meet and exceed OEM testing requirements and have been approved for use by many OEMs.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Dielectric

TECH LINE has developed both conductive and non-conductive coatings which, in addition, can provide corrosion and chemical resistance.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Thermal Management

Managing heat can be critical to the life and function of a component. By utilizing TECH LINE Thermal Barriers and Thermal Dispersant coatings, the flow of heat can be managed depending on the required end result. Using proper coatings, heat can be moved through a part or around a part, specific areas can be insulated, other areas can act as a greater radiating surface.

Coatings can increase part life, reduce dimensional change due to heat, reduce surface temperatures, reduce radiated heat, direct heat away from one area, transfer heat to a different area to better control the flow, reduce hot spots to provide even temperature over the surface of a part and more.

Coatings for thermal management can also provide increased corrosion and chemical protection, improve lubrication and release.

For your specific needs or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.

Appearance

TECH LINE knows that performance coatings not only need to function well, but they also need to look good, too.

Many of TECH LINE’s coatings are available in colors and with varying surface appearances from matte to gloss as well as a near chrome finish, polished stainless finish, cast iron finish, and more.

For your specific needs, colors, or finishes, or for more information, please contact our TECHNICAL DEPARTMENT at 865-773-0599.